RV roof sealant “tapes” such as Eterna Bond, Stick n Bond, Cofair Kwik Roof, Dicor Diseal, and Dicor lap sealant —self-leveling or non-sag — are both legit—just meant for different jobs. The best results usually come from using each where it makes sense.

RV roof sealant “tapes” such as Eterna Bond, Stick n Bond, Cofair Kwik Roof, Dicor Diseal, and Dicor lap sealant —self-leveling or non-sag — are both legit—just meant for different jobs. The best results usually come from using each where it makes sense.

1) What do people mean by “RV roof sealant tape”

The following 3 categories define the ordinary tapes used on RV Roofs. For better or Worse!

A) Microsealant roof tapes (most common “good” roof tape)

Example: EternaBond RoofSeal and similar.

- Pressure-sensitive adhesive designed for RV roofs; marketed as bonding to EPDM, TPO, fiberglass, metal, etc.

B) Butyl tapes (putty tape)

- Usually goes under flanges (vents, windows, trim) as a gasket, then you seal over the flange edges with lap sealant.

- Not typically the “topside seam tape” people picture.

C) “Hardware store” tapes (foil/HVAC/duct tapes)

- Generally not ideal for long-term roof waterproofing in UV/heat cycles. Only use Duct Tape as a very temporary fix. Duct Tape or Gorilla Tape can be very hard clean if left on too long or cooked in the sun.

2) Dicor lap sealant basics (what it’s great at)

Dicor self-leveling lap sealant is the classic RV roof go-to for horizontal surfaces around penetrations:

- Vents, skylights, antenna bases, ladder mounts, termination bars, screw heads, etc.

- Dicor’s own directions emphasize: clean, dry surface, caulking-gun application, and note cure progression (skins fast, waterproof in hours, full cure takes longer).

- Dicor also explicitly warns that self-leveling is not for vertical surfaces (you’d use a non-sag version for vertical surfaces).

Typical cure guidance from Dicor (50–70°F):

- ~5 min skin, ~4 hrs waterproof, ~48 hrs 80% cure, ~30 days full cure

3) RV Roof Sealant Tape vs Dicor lap sealant — practical pros/cons

RV Roof sealing tape (microsealant style)

Pros

- Awesome for long seams: front/rear cap seams, roof-to-sidewall transitions, long cracks/splits, puncture repairs.

- It can be very durable when applied to a properly prepped surface; it is marketed as UV/weather-resistant and compatible with common roof materials.

- Often a faster “done” repair than waiting on sealant cure (once it’s bonded and rolled).

Cons

- Surface prep is everything. Any chalky oxidation, dust, oil, or moisture = future edge lift.

- More “one-shot” to place neatly; it grabs aggressively.

- Many installations prefer warm tape/surface and firm rolling pressure; some instructions recommend ~70°F+ and proper primer use.

- Can hide problems (trapped moisture/rotted decking) if you tape over an active leak without fixing the underlying issue.

Dicor lap sealant (self-leveling / non-sag)

Pros

- Best for complex shapes and penetrations where tape wants to bridge/crease (vent corners, screw heads, irregular plastic flanges).

- Easy touch-ups and rework: scrape/reseal small sections as part of routine inspection.

- Designed for RV roof detailing; clear cure expectations.

Cons

- Requires ongoing inspection; exposure cycles can lead to cracking/shrinking over time depending on conditions.

- Not as slick for long seams (you can do it, but it’s messier and often needs rework sooner than a well-applied tape).

- Self-leveling isn’t for verticals.

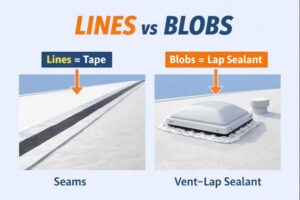

4) When to choose what (quick decision guide)

4) When to choose what (quick decision guide)

This is a guide – Not set in stone!

Use Dicor lap sealant when:

- You’re sealing around rooftop penetrations (vents, skylights, antenna, plumbing vent).

- You need sealant to flow around screw heads/edges and odd shapes.

- You’re doing routine “inspection-and-touch-up” maintenance.

Use RV roof sealant tape when:

- You’re sealing a long seam (cap seam, termination bar seam, roof membrane seam).

- You’re patching a tear/puncture or hairline crack that runs.

- You want a more “set it and forget it” seam approach—if you prep correctly.

Hybrid approach (very common in pro/DIY repairs):

- Tape the seam/patch and run a small bead of sealant at edges/terminations for extra insurance in tricky spots (some repair guides explicitly suggest tape + edge sealant).

- Download Quick Sealing Chart

5) Biggest success/failure factors (regardless of product)

5) Biggest success/failure factors (regardless of product)

- Clean + dry matters (Dicor explicitly says clean and let dry before applying).

- For tape: temperature + pressure/rolling matters a lot; many instructions stress keeping materials warm and using primer correctly.

- Don’t “seal over symptoms.” If there’s soft decking or wet insulation, sealing alone just buys time while damage spreads.

If you tell me your roof type (EPDM rubber, TPO, fiberglass, aluminum) and what you’re sealing (vent? front cap seam? tear?), I’ll give you a “use this product + this prep + this method” recommendation that fits the exact job.

When it comes to RV Roofs, we prefer Dicor Products over the other brands. Use this link to see the Dicor Product line.